Daily Business Report-Dec. 29,2017

Drill bits can be made using the sintering technique. (Courtesy of SDSU)

A Flash Forward for

Manufacturing Technology

By Michael Price | SDSU NewsCenter

Many materials manufactured today, including ceramics, tungsten carbide and diamond cutting tools, rely upon a technique called sintering. It turns a powdered substance into a solid mass—a process called densification—using heat and pressure. As described in a new study, engineers at San Diego State University have developed a twist on traditional sintering called “flash spark plasma sintering” that can densify materials in a matter of just seconds.

The new process is important because sintering is time- and energy-intensive. Redesigned sintering methods that require less energy and less time, and consequently reduce manufacturing costs, have been a focus of many research efforts over the past several years.

“This newly developed approach dramatically accelerates the time of synthesis, so that it occurs in a ‘flash’ — only seconds long — in contrast with regular spark-plasma sintering, which requires minutes, or regular sintering, which requires hours of processing time,” explained the study’s lead author, SDSU mechanical engineering professor and associate dean for research and graduate studies Eugene Olevsky.

Olevsky, along with postdoctoral fellow Charles Manière and Ph.D. student Geuntak Lee, designed the new technique that channels electrical current in narrowly focused areas of the material being sintered. So far, they’ve successfully tested flash spark plasma sintering by densifying samples of powdered nickel, aluminum oxid and zirconium dioxide, but it will work for any other powdered material that can be sintered.

“This technique turns out to be truly all-materials inclusive,” Olevsky said. “We’re able to demonstrate this using these three quite different material systems.”

Introducing controlled electrical fields is a major step forward for sintering technology, which has traditionally just relied upon extreme heat and pressure. The researchers recently descrobed their work with the new technique in journal Nature Scientific Reports.

Manufacturers who produce heavy-duty tools and machine parts out of powdered diamond, tungsten carbine or dozens of other powdered metals, as well as those who use ceramics for industrial uses, will be able to use the new technique to speed up production and save on energy costs, Olevsky said.

The success is a testament to SDSU’s engineering department and specifically its reputation in the world of sintering research. Olevsky’s work in this area, as well as in bioengineering and energy research, will continue inside his lab in the SDSU’s new

Engineering and Interdisciplinatry Sciences Complex, slated to open in January.

“This breakthrough reflects the strength of SDSU engineering programs and in particular in the area of advanced materials research,” Olevsky said. “SDSU is internationally known as the world center of sintering research.”

Partially adapted from a release written by April Gocha.

________________

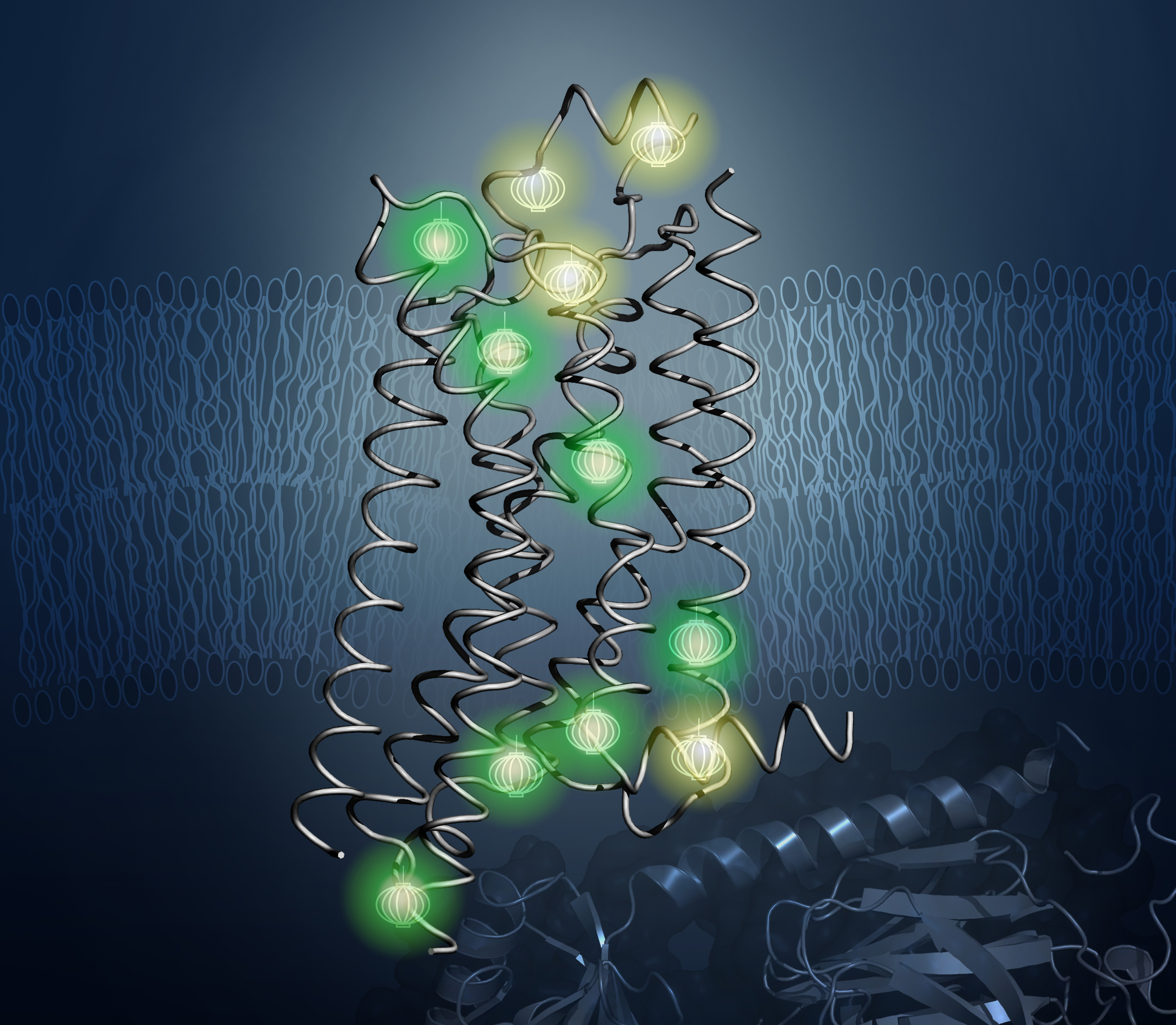

New Structure of Key Protein Holds

Clues for Better Drug Design

Scientists at The Scripps Research Institute (TSRI) have peered deep into the heart of a key protein used in drug design and discovered dynamic structural features that may lead to new ways to target diseases. The protein, called the A2A adenosine receptor (A2aAR), is a member of the G-protein-coupled receptor (GPCR) family, which are the targets of roughly 40 percent of all approved pharmaceuticals.

The new, more detailed image of A2aAR’s signaling mechanism reveals key parts of its inner workings, including an amino acid that acts like a “toggle switch” to control signaling across the cell membrane.

“This basic knowledge is potentially helpful for improving drug design,” says Nobel laureate Kurt

Wüthrich, the Cecil H. and Ida M. Green Professor of Structural Biology at TSRI and senior author of the study.

The findings were published in the journal Cell.

________________

SCORE San Diego Moves to New Location

SCORE San Diego will be moving to a new office at 8825 Aero Drive, Suite 1012, San Diego, 92123 on Jan. 1, 2018. All chapter services will be provided at the new location including mentoring, workshops, and Executive Leadership Forums. According to Chapter Chair Sally Broff, “The executive board felt that we could improve our services to entrepreneurs and small businesses by relocating to a larger facility where they can provide private and confidential mentoring and seat 36 in a professional workshop setting. The New location offers easy access and free parking for SCORE clients.

The SCORE Association has 300 chapters across the US and approximately 11,000 volunteers. The San Diego Chapter has over 80 volunteers with a broad variety of business experience. SCORE is a resource partner of the Small Business Administration, providing free private mentoring in-person, over the telephone, by email, and on video.

________________

Northrop to Implement Army ‘Hunter’

UAV Engineering Change Proposal

ExecutiveBIZ

Northrop Grumman has secured a $12.7 million contract modification to incorporate an engineering change proposal into the payload technology of the U.S. Army‘s Hunterunmanned aerial vehicle.

The Defense Department said Northrop will perform work in Sierra Vista, Arizona through Oct. 20, 2018.

The Army Contracting Command obligated $6.2 million at the time of award from the military branch’s fiscal year 2017 procurement funds.

Northrop developed Hunter to support intelligence, surveillance and reconnaissance efforts of Army division and corps commanders.